Digital Twins and the Industrial Metaverse

Digital Twins and the Industrial Metaverse

by vivienne 11:50am Jan 09, 2025

Digital Twins and the Industrial Metaverse are two rapidly evolving technologies that are transforming how industries operate, make decisions, and innovate. While Digital Twins focus on creating digital replicas of physical entities, the Industrial Metaverse provides a virtual environment where these digital twins can interact, simulate, and evolve in real time. Together, they represent the next frontier in industrial operations, allowing businesses to optimize processes, predict outcomes, and improve efficiency on an unprecedented scale.

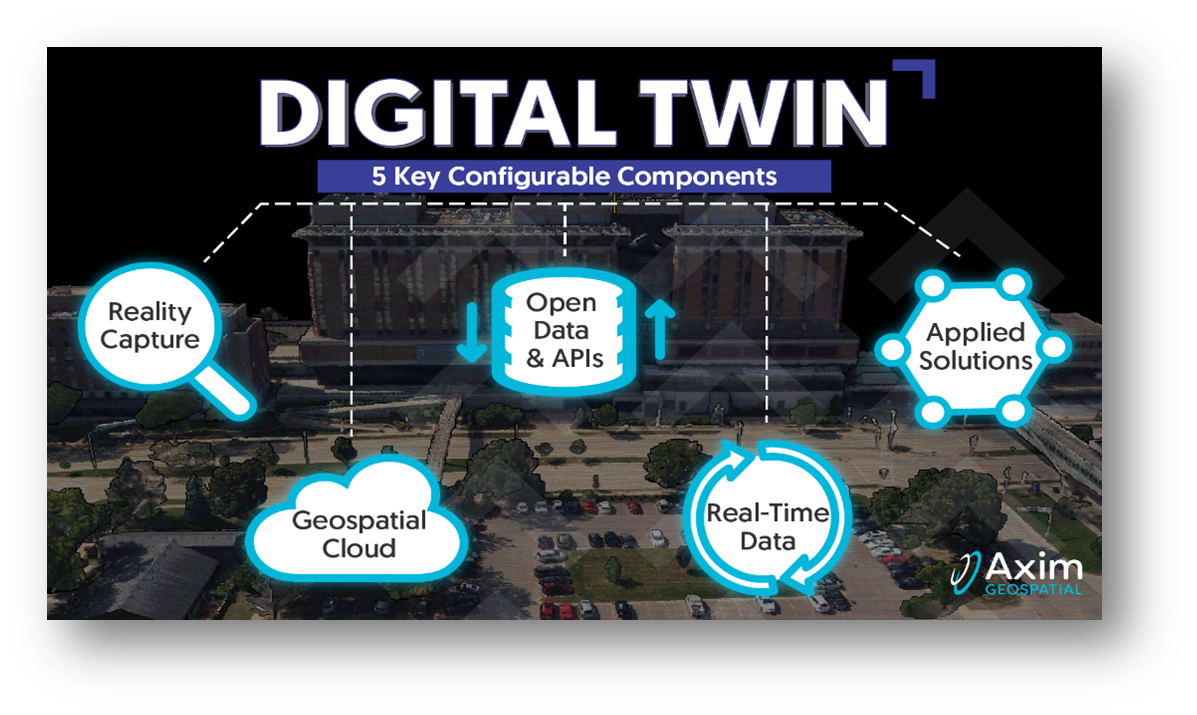

What Are Digital Twins?

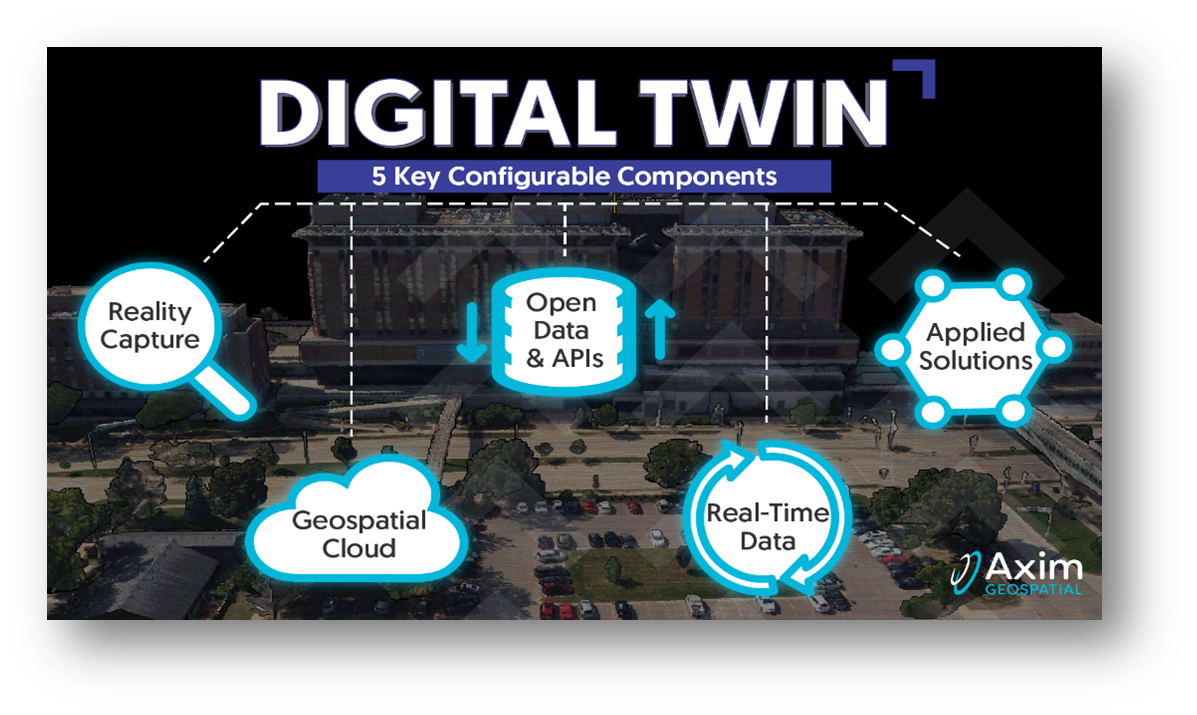

A digital twin is a virtual replica of a physical asset, process, or system that captures real-time data from sensors and IoT devices. This allows the virtual model to reflect the real-world asset’s status, condition, and behavior. Digital twins can represent anything from machinery in a factory to an entire city, enabling:

· Predictive Maintenance: By monitoring assets, digital twins can predict issues before they arise, reducing downtime.

· Improved Design and Simulation: Engineers can simulate modifications in the virtual model to analyze potential impacts without disrupting the actual system.

· Real-time Monitoring and Optimization: Digital twins provide an up-to-date view of operations, allowing for better decision-making and efficiency.

In sectors like manufacturing, energy, and healthcare, digital twins are pivotal for optimizing performance, saving costs, and improving safety.

The Industrial Metaverse

The industrial metaverse expands on digital twins by creating a shared, immersive virtual space where industrial assets, processes, and personnel coexist digitally. It combines advanced technologies like virtual reality (VR), augmented reality (AR), IoT, 5G, and AI. This is an evolution from using isolated digital twins to building interconnected, collaborative environments that offer new ways of working and innovating. In the industrial metaverse, digital twins serve as building blocks for an immersive experience where employees, engineers, and managers can:

· Collaborate Remotely: Workers from different locations can meet in virtual spaces to interact with digital replicas of equipment.

· Enhance Training: Immersive environments help train employees in simulated, risk-free settings.

· Optimize Operations: By visualizing and analyzing systems in real-time, teams can improve workflows, safety protocols, and asset utilization.

The industrial metaverse enables comprehensive, data-driven decision-making by combining digital twins with immersive experiences and real-time, interactive simulations. This approach is poised to drive efficiency, sustainability, and innovation in manufacturing, logistics, energy, and beyond.

Future Outlook

As technology advances, digital twins and the industrial metaverse will likely become even more integral, driven by increasing data volumes, AI advancements, and connectivity improvements. With these developments, industries can expect enhanced automation, predictive insights, and collaborative opportunities that will transform industrial processes and potentially open up new business models.