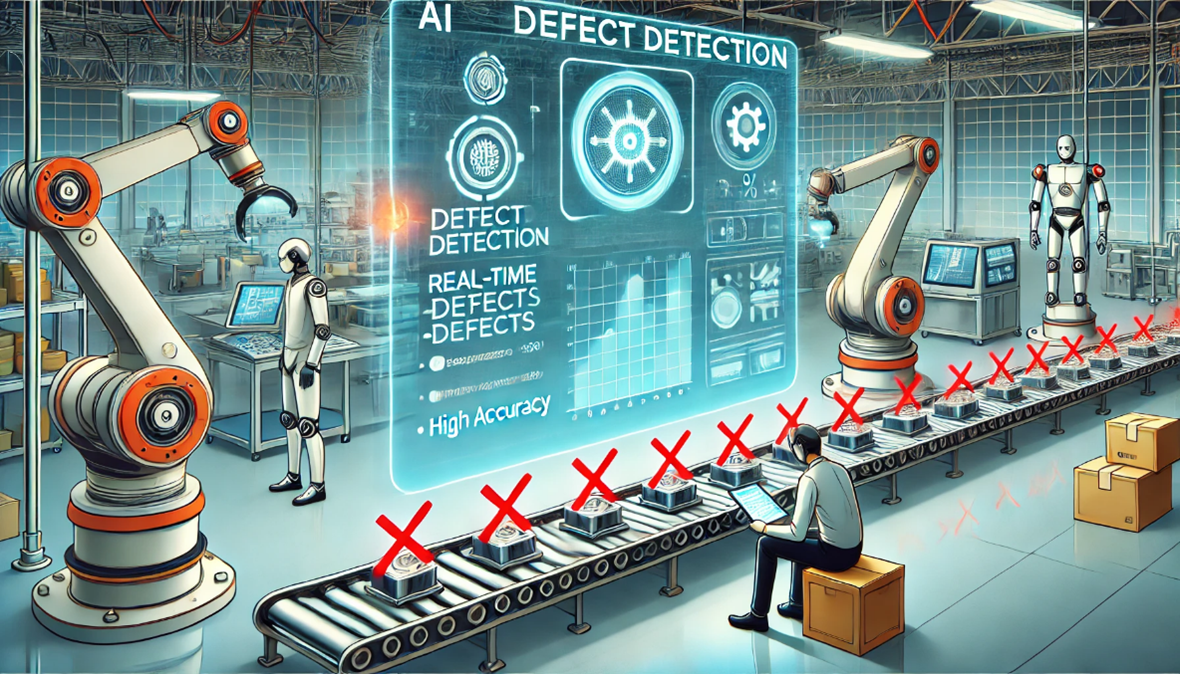

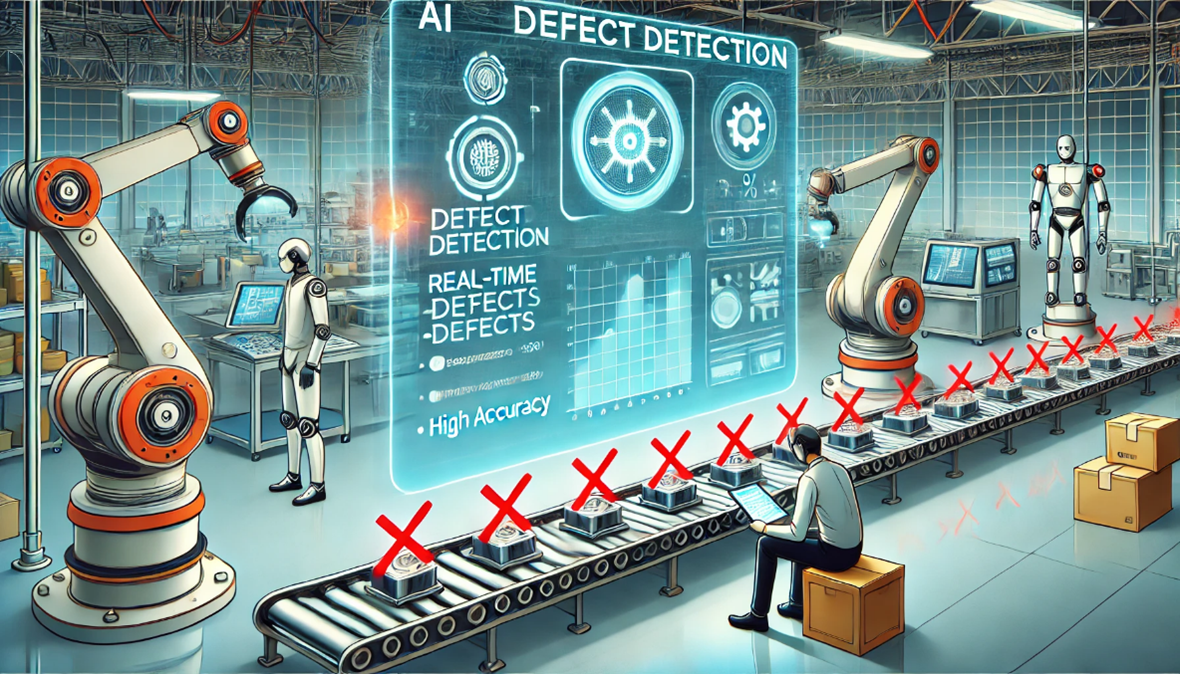

How can AI enable real-time defect detection and quality assurance on production lines?

How can AI enable real-time defect detection and quality assurance on production lines?

by Maximilian 11:47am Jan 25, 2025

AI enables real-time defect detection and quality assurance on production lines by leveraging advanced technologies such as computer vision, machine learning, and real-time analytics. These tools automate inspection processes, ensuring consistent quality and reducing the chances of defective products reaching customers. Here's how AI achieves this:

1. Automated Visual Inspection

Computer Vision Systems: AI-powered cameras and image processing algorithms analyze products in real time.

Defect Identification: Detects surface defects, dimensional inaccuracies, or missing components by comparing products against predefined standards.

High-Speed Processing: Inspects hundreds or thousands of items per minute, far surpassing human capabilities.

2. Advanced Machine Learning Models

Supervised Learning: Models trained on labeled datasets identify defects like cracks, scratches, or discolorations.

Unsupervised Learning: Detects anomalies without prior labeling by learning the "normal" characteristics of products.

Deep Learning: Handles complex visual tasks, such as identifying subtle defects or patterns in non-uniform products.

3. Multi-Sensor Data Integration

AI integrates data from various sensors for comprehensive quality checks:

Thermal Cameras: Detects overheating or temperature anomalies in electronic components.

Ultrasound Sensors: Identifies internal defects like voids or cracks in materials.

Spectroscopy Sensors: Ensures material composition meets specifications.

4. Real-Time Feedback and Correction

Immediate Alerts: AI flags defective products in real time, allowing operators to remove them from the production line.

Adaptive Processes: AI adjusts machine settings dynamically (e.g., tightening tolerances, recalibrating tools) to prevent recurring defects.

Process Optimization: Identifies root causes of defects, enabling continuous process improvements.

5. Digital Twins and Predictive Analytics

Digital Twin Integration: Simulates the production process to predict potential defects based on environmental or operational changes.

Predictive Quality Assurance: Analyzes historical defect data to forecast and mitigate future quality issues.

6. Benefits of AI-Driven Defect Detection

Higher Accuracy: Detects even minor defects that may be missed by human inspectors.

Reduced Downtime: Real-time monitoring helps address issues before they escalate.

Improved Yield: Minimizes waste by identifying and addressing problems early in the production cycle.

Scalability: Easily adaptable to different product lines or defect criteria.

7. Use Cases Across Industries

Electronics: Identifying soldering defects on circuit boards.

Automotive: Detecting paint imperfections or alignment issues in vehicle assembly.

Pharmaceuticals: Ensuring capsule or tablet uniformity and labeling accuracy.

Textiles: Identifying weaving errors, discolorations, or tears in fabrics.

8. Challenges and Solutions

Data Quality: High-quality training datasets are essential for effective defect detection.

Solution: Use synthetic data augmentation or collect diverse real-world samples.

System Costs: Initial deployment of AI systems can be expensive.

Solution: Cloud-based AI models reduce hardware costs.

Complex Defect Types: Some defects may require domain-specific knowledge.

Solution: Combine AI models with expert oversight during system setup.

9. Examples of AI Technologies in Use

NVIDIA Metropolis: Enables high-speed defect detection using edge computing and AI.

AWS Lookout for Vision: Provides scalable, pre-trained models for visual anomaly detection.

Cognex Vision Pro: Offers AI-powered tools for real-time quality assurance in manufacturing.

By enabling real-time defect detection, AI not only ensures consistent product quality but also reduces costs, increases efficiency, and enhances customer satisfaction in modern manufacturing processes.