How can machine learning improve warehouse automation and real-time inventory tracking?

How can machine learning improve warehouse automation and real-time inventory tracking?

by Maximilian 04:30pm Jan 28, 2025

Machine learning (ML) significantly enhances warehouse automation and real-time inventory tracking by improving accuracy, efficiency, and adaptability. Here’s how it works:

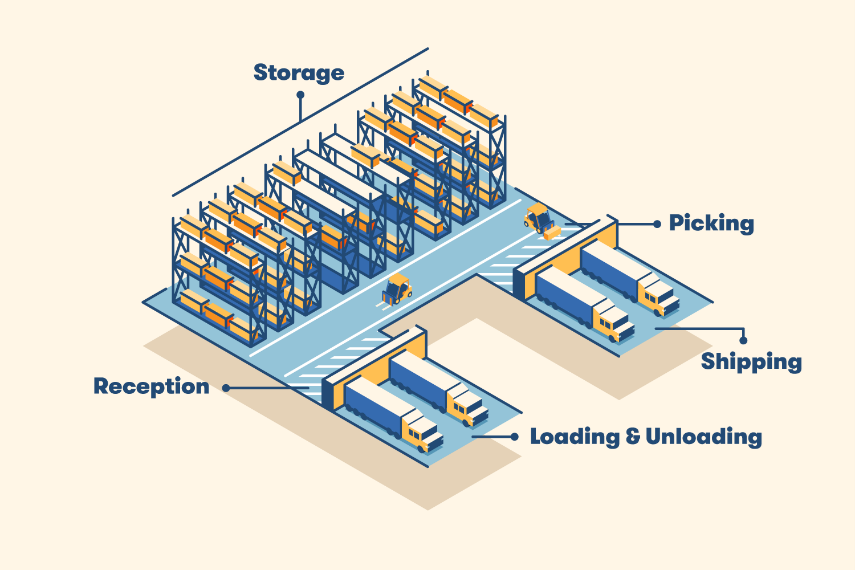

1. Optimizing Warehouse Layout and Operations

Dynamic Layout Planning: ML algorithms analyze product demand patterns to optimize warehouse layouts, ensuring frequently picked items are closer to shipping areas.

Path Optimization: ML-powered systems calculate the shortest and most efficient routes for workers or robots, reducing travel time and operational costs.

Task Prioritization: ML prioritizes tasks such as restocking or order picking based on deadlines, inventory levels, and demand predictions.

2. Real-Time Inventory Tracking

IoT Integration: IoT sensors combined with ML monitor inventory levels and locations in real time, ensuring precise tracking of goods.

Automated Stock Updates: ML processes data from scanners, RFID tags, and IoT devices to update inventory levels automatically, reducing human errors.

Demand Sensing: ML predicts stock replenishment needs based on real-time sales data and external factors like seasonal trends or weather.

3. Enhancing Picking and Packing Processes

Intelligent Picking Systems: ML improves robotic picking systems by teaching them to recognize items using computer vision, handling complex tasks like picking fragile or irregularly shaped items.

Error Reduction: ML algorithms detect anomalies, such as incorrect items or quantities during picking and packing, minimizing order errors.

Packing Optimization: ML analyzes order contents to suggest the most efficient packing arrangements, reducing packaging waste and space usage.

4. Predictive Maintenance of Equipment

Machine Health Monitoring: ML analyzes sensor data from warehouse machinery to predict maintenance needs, preventing unexpected breakdowns.

Optimized Downtime Scheduling: Maintenance is scheduled at the least disruptive times, improving overall efficiency.

5. Inventory Forecasting and Stock Optimization

Demand Forecasting: ML predicts demand trends with high accuracy, helping warehouses stock the right amount of inventory to avoid overstocking or stockouts.

Shelf-Life Management: For perishable goods, ML identifies items nearing expiration and suggests actions like discounts or prioritizing their picking.

6. Enhancing Worker Productivity and Safety

Wearable Technology Insights: ML analyzes data from wearable devices to monitor worker productivity and suggest ergonomic improvements.

Safety Monitoring: ML detects potential safety risks (e.g., blocked paths, overloaded shelves) using video and sensor data, issuing real-time alerts.

7. Advanced Robotics and Automation

Collaborative Robots (Cobots): ML enables cobots to work alongside humans, adapting to changing environments and tasks.

Autonomous Vehicles: ML guides automated guided vehicles (AGVs) and drones to navigate warehouses efficiently, even in dynamic settings.

8. Fraud and Loss Prevention

Anomaly Detection: ML identifies irregularities in inventory records or movements, signaling potential theft or errors.

Video Surveillance: Computer vision algorithms detect unauthorized access or suspicious activity in warehouses.

Real-World Examples

Amazon: Uses ML to power robots in fulfillment centers, optimizing picking, sorting, and packing.

Ocado: Employs ML-driven robots and predictive analytics for highly efficient grocery warehouse operations.

Zebra Technologies: Combines ML with RFID tracking for real-time inventory visibility and smarter workflows.

In Summary

Machine learning transforms warehouse automation and inventory tracking by improving efficiency, accuracy, and adaptability. It minimizes errors, enhances safety, and ensures real-time visibility, ultimately leading to cost savings and better customer satisfaction.